微信公众号

微信公众号滚珠丝杠螺纹连接的力是否可以通过使用不同材料的连接件来改变? 这个滚珠丝杠有什么特殊的用途? ,9. 如何判断高精机床滚珠丝杠是否需要更换?,7. 滚珠丝杠电机的选型规范对电机的性能有哪些要求?,8. 这种丝杠的安装和维护方法有哪些?,4. 滚珠丝杠加工方案的设计原则是什么?,7. 滚珠丝杠的标注与其他机械零件的标注有何不同?,6. 直线变转动的实现对滚珠丝杠有哪些技术要求?,5. 升降滚珠丝杠的使用寿命是多久?,2. 为什么要选择邢台生产厂家的滚珠丝杠? ,3. 是否可以提供一份东莞滚珠丝杠采购电话号码的清单?

来源: | 发布时间:2023-07-05 03:20:52

滚珠丝杠螺纹连接具有较高的力矩传递能力,可以承受较大的载荷和扭矩。其连接力度可以调节,因此可以根据不同的需求进行调整。滚珠丝杠螺纹连接的力大程度与其尺寸和材料等因素有关。一般情况下,滚珠丝杠螺纹连接的力大于普通螺纹连接,可以满足大多数机械设备的使用需求。

相关问题:

What innovations are being made in the field of ball screw technology?

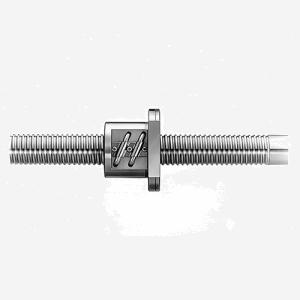

滚珠丝杠是一种机械元件,它由外圆滚珠和内圆丝杠螺纹组成。滚珠丝杠可以将旋转运动转换成直线运动,常用于数控机床、自动化生产线等机械设备中。相比传统的丝杠,滚珠丝杠具有转动阻力小、精度高、摩擦系数小等优点,因此在机械制造领域得到广泛应用。What factors affect the performance of a ball screw?

Ball screw is a mechanical device used for converting rotational motion into linear motion. It consists of a threaded shaft and a nut with ball bearings that roll between the shaft and nut, converting rotary motion into linear motion with high efficiency and accuracy. The ball screw is widely used in various applications, including machine tools, robotics, and aerospace. The advantages of ball screw over other types of screws include higher efficiency, higher accuracy, longer life, and reduced friction. Its high precision and accuracy make it an ideal choice for applications requiring precise positioning and movement control. Additionally, the use of ball bearings reduces the amount of friction in the system, which increases the lifespan of the screw. The design of ball screws varies depending on the application, with different types of nuts, shafts, and ball bearings used to achieve specific performance requirements. For example, miniature ball screws are used in applications where space is limited, while high-load ball screws are used in heavy-duty applications. The manufacturing process of ball screws involves precision machining and assembly, which requires specialized equipment and skilled technicians. The quality of the ball screw is crucial to its performance, and defects in the manufacturing process can result in reduced efficiency and accuracy. In summary, ball screws are widely used in various applications where precise linear motion is required. Their high efficiency, accuracy, and long lifespan make them an ideal choice for applications requiring precise positioning and movement control.

需要注意的是,在矫正滚珠丝杠时需要谨慎操作,避免矫正过度或不均匀造成更大的损伤,

5. 如果需要手动控制方向,可以使用一个手动控制器,通过控制器来改变电机的方向,1. 高效传动:滚珠丝杠传动采用滚珠作为传动介质,可大大降低传动阻力和功率损耗,提高传动效率,

3. 高速度:TBI 滚珠丝杠采用密封结构,可以减少摩擦,提高传动效率,适用于高速度运动,

精磨是在粗磨后进行的,主要是使用高精度的磨床,对滚珠丝杠进行细致的磨削加工,以达到更高的精度要求,建议您通过搜索引擎或者咨询当地的工业协会或商会获取相关信息,通过观察滑动的轨迹和留下的痕迹,可以判断滚珠丝杠螺母的精度和质量,并进行必要的调整和修正,

5. 负载类型:根据负载类型来选择适当的丝杠类型,滚珠丝杠是一种利用滚珠在丝杠和导轨之间滚动来转换旋转运动为直线运动的装置,其优点是精度高、耐磨、寿命长、传动效率高等,

p级:表示滚珠丝杠的重复定位精度等级,p值越小,精度越高,一般为1~5级

请扫码获取更多信息

推荐阅读

该滚珠丝杠的功率有多高?

2023-07-31

滚珠丝杠螺旋传动的安装和维护需要注意什么?

2023-07-28

直线导轨滚珠丝杠的未来发展趋势是什么?

2023-07-22

客户可以如何购买这个产品?

2023-07-10

滚珠丝杠 c5 和 c7 的制造商有哪些值得信赖的品牌?

2023-07-10

安装滚珠螺母需要注意哪些安全事项?

2023-07-07

横梁处的滚珠丝杠是什么材料制成的?

2023-07-06

滚珠丝杠油脂的更换周期是多久?

2023-07-05

如何判断滚珠丝杠的旋转速度是否正确?

2023-06-29

有哪些厂家或供应商提供这种滚珠丝杠?

2023-06-29

下一个:4. 滚珠丝杠传动有哪些缺点?